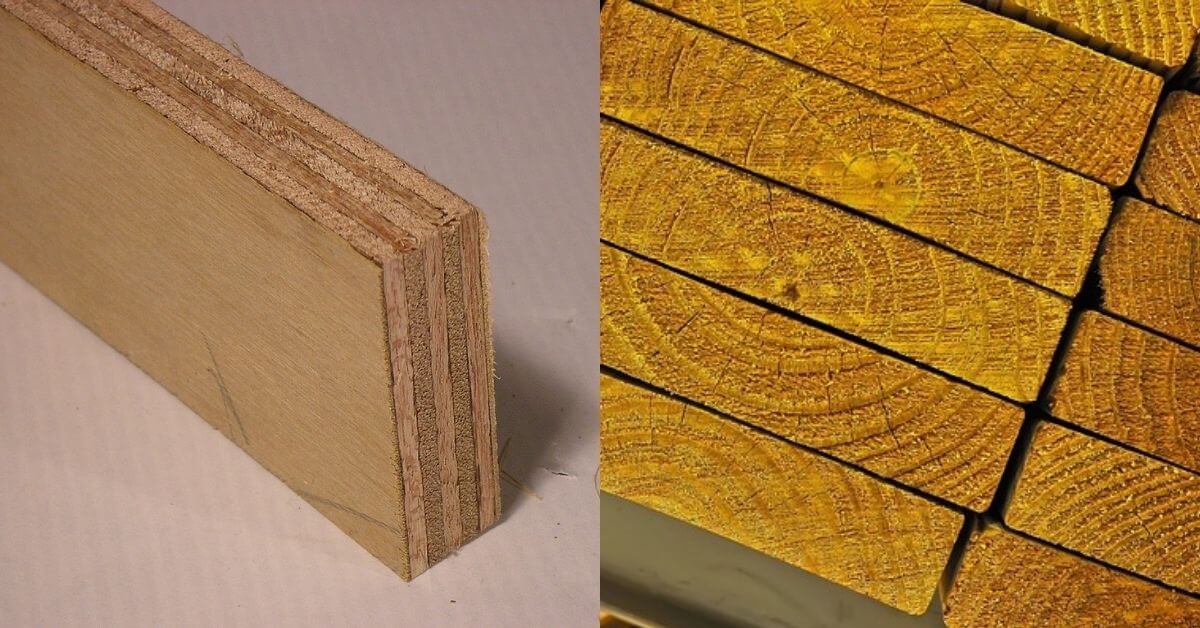

Solid wood and Plywood are very useful materials for construction. Plywood is an engineered product and Plywood made by gluing multiple layers of wood veneer. Whereas solid wood we get directly from the tree.

Plywood is stronger than solid wood against bending forces. But solid wood is more durable and stable for outdoor environments. Plywood is used instead of solid wood for many purposes. But for some purposes, solid cannot be replaced with plywood. Both are better for their uses.

First, Plywood was introduced into the United States in 1865. Due to its amazing characteristics, it is now used all over the world for many purposes.

You might be familiar with solid wood. Solid wood is directly obtained from the tree. But there is some process to making wood or lumber from trees.

| # | Plywood | Solid Wood |

| Appearance | Looks almost like wood. | looks more attractive |

| Workability | Great | Good |

| Durability | Good | Very good |

| Uses | Crates, bins, internal structures | Furniture, cabinetry, and flooring, fencing, siding, making houses |

Plywood vs Solid wood Uses

Uses of plywood

Plywood is a versatile engineered product and is used in almost every type of building project. Plywood is used for crates, bins, internal structures, indoor furniture, and boxes, etc.

Many manufacturing companies make plywood for a specific purpose. Which is stronger, durable, and more expensive. Such as Aircraft Plywood, marine plywood, Moisture Resistant Plywood, etc.

Aircraft Plywood uses: It is the most durable and expensive type of plywood. It is more flexible, lightweight, and extremely stronger than other plywood. It is used in fighter aircraft. Aircraft plywood was used in world war 2.

Marine plywood uses: Marine-grade plywood is better for moisture and humid conditions. It is used for Boats, Bathrooms, Docks, Bathrooms, Kitchens. Here is a marine-grade plywood alternative.

Moisture Resistant Plywood uses: It is also called MR ply or commercial ply. Moisture Resistant Plywood is resistant to moisture in humid and damp conditions and a great option for exterior application.

Uses of Solid wood

Solid wood is used for all types of construction. It is mainly used for furniture, cabinetry and flooring, fencing, siding, making houses, musical instruments, sports equipment, packaging, and many more.

The use of wood also depends on the type of wood. There are two types of wood, softwood, and hardwood.

Hardwood: Hardwood is mainly used for flooring. Apart from this Hardwood is the best option for cladding, paneling, cabinetry, fencing, boats, and outdoor decks. Some hardwood species are oak, maple, and cherry.

Softwood: Softwood is mainly used for interior applications such as windows, doors, furniture items, paper, etc. Because most softwood species are lighter, flexible, and have a lower density than hardwoods. Some softwood species are cedar, Douglas fir, juniper, pine, redwood.

Plywood vs Solid wood Strength

The strength of solid wood is higher than regular plywood. Plywood is made up of multiple thin sheets of wood that are glued together with adhesive. Plywood veneers can crack due to moisture and heavy pressure. Therefore, plywood does not have the same strength as solid wood.

But it is not necessary that solid wood furniture is always strong, it is very important to have the right design of the furniture, and the wood species should also be selected correctly for good strength.

But there are many such wood species that have very good load capacity or great strength such as Maple, Oak, lignum vitae, and many more.

Plywood vs Solid wood Appearance

Plywood is made by using wooden veneers. Hence the upper surface almost looks like solid wood. But the Appearance of Solid Wood cannot be compared to plywood or any other material.

Plywood cannot be used for making decorative objects because plywood can never give a wood-like touch and feel.

Solid wood can be sanded, polished, and painted over and over again. But plywood is cannot be done more than once or twice.

Maintenance

Plywood and solid wood both require regular maintenance. Some solid woods have natural rot resistance and medium water resistance properties and good-quality plywood require less maintenance. But it would be right to maintain it every one to two years. Regular care maintains natural grain pattern.

Furniture with paint, polish, and laminates require less maintenance. Since laminates do not allow moisture and dust to settle on the surface. So there is less chance of damage.

Plywood starts to rot from its edge, so its edge should be sealed. If plywood is used outdoors then exterior finishing is required.

Workability

The workability of plywood is great compared to solid wood. Plywood can be cut and bent more easily than solid wood.

Due to the irregular grain in some wood species such as Chestnut, Hackberry, and Osage-orange. Working with these species can be a bit difficult.

But not all wood species have the problem of workability, some wood species having low densities and straight grain patterns such as cherry wood, balsa, cedar, cedar, etc. These species are easy to work with hand tools and machines.

Availability

Plywood is used all over the world and manufactured in almost every country. Furniture made of plywood is present in almost every home. But many people are unaware that there is something made of plywood in their house.

Plywood is available in many sizes and thicknesses. Plywood is available in sizes 2 x 2 feet, 2 x 4 feet, and 4 x 4 feet, 4 x 10 feet, 6, 8, and 10 feet in length, and thickness is 1/8″, 1/4″, 3/8″, 1/2″, 5/8″, 3/4″, and 1-1/8″.

Certain species of wood that are found in one region can be expensive for another region. But you get wood of many sizes and thicknesses.

Is plywood waterproof?

Most of the owners have this question, Is plywood waterproof or can we use plywood for wet places such as bathrooms and exterior places?

The short answer is yes, There are many types of plywood available, which perform well even after continuous exposure to moisture and water. Such as BWP (Boiling Waterproof) Grade Plywood.

The long answer is, nothing made of wood can be 100% waterproof. Just some plywood grades perform better than regular plywood for a long period of time, even after being exposed to moisture and water.

I am sharing some experiments with you. So that you will be able to differentiate between regular plywood and solid wood.

You can see the condition of the plywood after it has been out for 2 years.

You can see the condition of solid wood by keeping it outside for 2 years.

Types of plywood

Softwood plywood

Softwood plywood is mainly made of softwood, such as cedar, redwood, Douglas fir or spruce, pine, fir, etc. Their density is less than that of hardwood. This hardwood is weaker and cheaper than plywood.

Hardwood Plywood

Hardwood wood is used to make hardwood plywood such as Oak, Beech, and Mahogany, etc. They have a higher density and weight than softwood plywood. Hardwood plywood is characterized by its excellent strength, stiffness, and resistance to creep.

Types of Wood

Although there are many types of wood, but the group of wood can be divided into two parts: Softwood and Hardwood.

Softwoods are open-grained which come from coniferous trees like pine, cedar, and etc. Hardwoods are close-grained and are strong and heavy like oak, teak, mahogany, and etc.