Cocobolo wood is a tropical hardwood native to Central America, mostly found in Nicaragua, Costa Rica, Panama, and parts of Mexico. It is highly valued for its appearance, density, durability, rot, and insect-resistant properties.

The cocobolo tree is heavily harvested due to the high price of the wood, and the tree grows at a very slow rate, taking decades to reach maturity, which has led to a sharp decline in the cocobolo population over the past few decades. Due to the shortage of wood in the international market, it is rare and valuable.

Quick Details of Cocobolo Wood

| Scientific Name | Dalbergia retusa |

| Tree Size | 40-60 ft (13-18 m) tall, 1-2 ft (30-60 cm) trunk diameter |

| Color | Brown with streaks of black or purple |

| Average Dried Weight | 68.5 lbs/ft3 (1,095 kg/m3) |

| Janka Hardness | 2,960 lbf (14,140 N) |

| Crushing Strength | 11,790 lbf/in2 (81.3 MPa)* |

| Type | Hardwood |

Cocobolo Wood Characteristics

Strength

Cocobolo wood is known to be one of the hardest and densest woods, making it extremely durable and strong. It contains natural oils, which makes it insect and weather resistant

Color and Texture

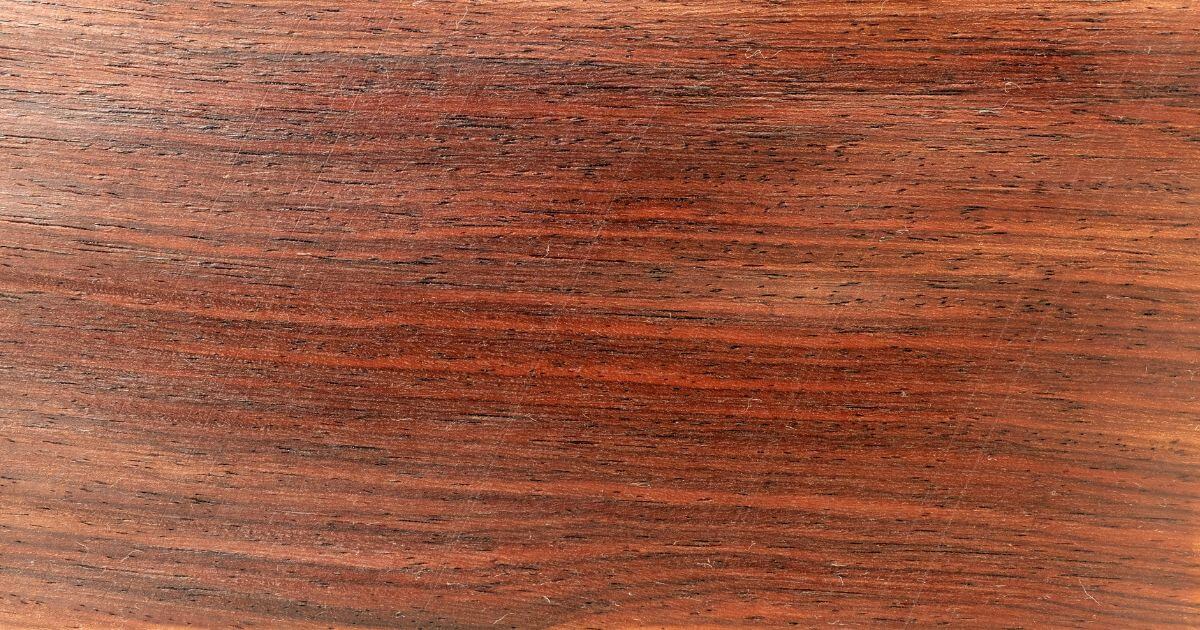

The heartwood of the cocobolo is typically ranging from yellow, orange, red, and brown with stripes of black or dark brown. Sapwood can be light brown to pale yellow.

Cocobolo wood has a straight interlocked grain pattern with a fine, even texture. Wooden tents darken over time, and the surface becomes oily and shiny.

What is Cocobolo Wood Used For?

Cocobolo wood is naturally water resistant, so it is suitable for both indoor and outdoor applications; wood can be used for:

Furniture Making

The primary use of cocobolo wood is for making high-quality furniture. Because it is strong and durable, and it also looks great. Its attractive color and grain patterns make it a favorite among craftsmen and interior designers alike.

Flooring

As we all know that cocobolo wood is harder and more durable than most wood species, making it an excellent choice for high-end floors and it is also less prone to dents and scratches.

Musical Instruments

Cocobolo wood is also preferred in the manufacture of musical instruments, such as acoustic guitars, clarinets, and oboes. It produces a clear and responsive tone.

Tools Handles and Grips

The wood’s durability and resistance to moisture make it an excellent choice for making knife handles and grips.

Small Decorative Items

Cocobolo wood is widely used for making small decorative items such as bowls, pens, chess pieces, and boxes.

Pros of Using Cocobolo Wood

Aesthetics and Unique Grain Patterns

Cocobolo Wood is popular for its dark vibrant color, with black streaks and a striking grain pattern. It has natural oily properties, which enhance the appearance of finished products.

Durability and Resistance to Decay

Cocobolo wood is considered a very durable and stable wood. It is naturally rot and insect-resistant, making excellent choices for outdoor projects.

Excellent finishing

Cocobolo wood is very well finished. Its oily surface gives it a shine and smooth appearance.

Versatility

Cocobolo wood is considered a versatile wood because of its wide range of applications. Its beauty, unique colors, and attractive grain patterns make it a popular choice for crafting high-quality furniture and musical instruments.

Cons of Using Cocobolo Wood

Cost and Rarity

The high demand and limited supply of cocobolo wood contribute to its relatively high cost compared to other types of wood.

Hard to work with

Cocobolo wood is difficult to work with as it is very hard and can dull tool blades very quickly. The wood has a lot of natural oils, making it difficult to glue.

Allergic Reactions

Skin, eye, and respiratory irritation are common problems noticed while working with Cocobolo wood. An asthma patient should avoid working with Cocobolo wood.

Environmental Concerns

Due to its popularity, excessive harvesting of cocobolo wood can create environmental concerns and threaten the sustainability of cocobolo trees.

Cocobolo Wood Hardness

Cocobolo wood is known for its extreme hardness and density. It typically has a Janka hardness rating of around 2,960 pounds-force (lbf). It is one of the hardest woods in the world.

However, the high density and weight of cocobolo wood can make it challenging to work with for a beginner. Working smoothly with it requires sharp tools and a skilled woodworker.

Here are the Janka hardness of other popular wood species to give you an idea of how hard cocobolo wood is.

| Wood species | Janka Hardness |

| Wenge | 1,930 lbf (8,600 N) |

| Black Mesquite | 1,940 lbf (8,630 N) |

| Bubinga | 2,410 lbf (10,720 N) |

| Amazon Rosewood | 2,700 lbf (11,990 N) |

| Cocobolo Wood | 2,960 lbf (14,140 N) |

| Gaboon Ebony | 3,080 lbf (13,700 N) |

| Bulletwood | 3,130 lbf (13,920 N) |

| Burmese Blackwood | 3,350 lbf (14,900 N) |

| African blackwood | 3,670 lbf (16,320 N) |

| Snakewood | 3,800 lbf (16,900 N) |

Maintenance and Care of Cocobolo Wood Products

Although it is a hard and strong wood that requires little maintenance compared to other hardwoods, it is still a wood material that can deteriorate if not cleaned and cared for from time to time.

To maintain the natural color of cocobolo wood projects, regular cleaning and care with natural oils is recommended. Avoid using harsh chemicals that can strip the wood of its natural color.

Conclusion

The unique beauty, strength, and durability of cocobolo wood make it a highly prized hardwood. Cocobolo wood has versatile uses, from furniture to musical instruments. However, its popularity and limited supply require responsible sourcing to ensure its sustainability for future generations.

FAQs

Where Does Cocobolo Wood Come From?

Cocobolo wood comes from the small to medium-sized deciduous cocobolo tree (Dalbergia retusa), which is native to Central America; because of the Cocobolo tree’s slow growth rate, cocobolo wood is considered an expensive and rare wood.

However, the Cocobolo tree is so heavily harvested, So it is listed in CITES Appendix II under the genus-wide restriction on all Dalbergia species.

Is Cocobolo Wood Toxic?

Cocobolo Wood is not considered toxic, but when working with Cocobolo wood, whether cutting, sanding, or shaping, fine wood dust particles can cause skin, eye, and respiratory irritation.

Therefore, while working with wood like Cocobolo Wood, take necessary precautions like wearing appropriate personal protective equipment (PPE), such as a dust mask, safety goggles, and gloves.