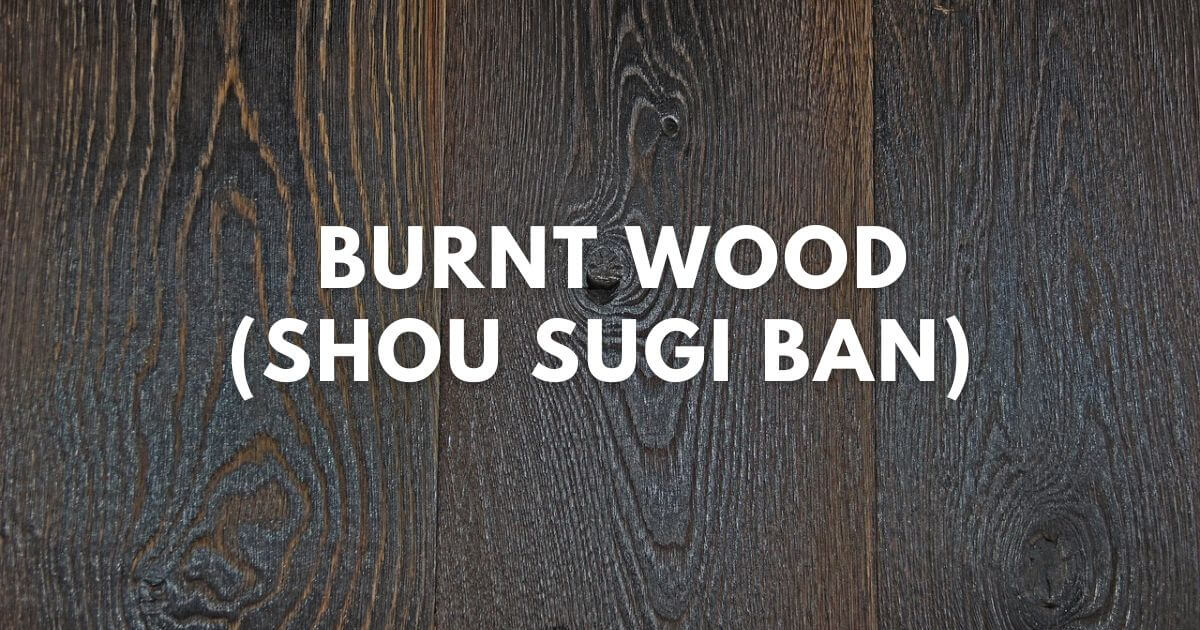

Burnt wood is another great option for rot and moisture-resistant purposes. The outer surface of the wood is charred, which preserves and increases the life of the wood. This ancient Japanese technique, called Shou Sugi Ban or Yakisuki, was invented in Japan.

Burnt wood, also known as charred wood or scorched wood. It has been used for many centuries in Japan and some Asian countries.

Burnt wood Uses

Burnt or charred wood has versatile uses, both practical and aesthetic. Here are some common uses:

Architectural and Interior Design:

Burnt wood is often used in interior design projects to create a unique appearance. It can be used for wall cladding, ceilings, or furniture pieces, adding a distinct and rustic look to the space.

Outdoor Decking and Siding:

Since the charring process makes the wood more resistant to decay, pests and weathering, therefore burnt wood can typically be used in outdoor applications such as decking and siding.

Art and Sculpture:

Artists and sculptors often use burnt wood to create amazing artwork. Burnished textures and deep dark tones can add depth and character to sculptures and carvings.

Garden Uses:

In landscape design, charred wood can be used for outdoor structures, such as garden fences, pergolas, and trellises. It does not rot even after coming in contact with the garden soil.

What is the process of burnt wood?

Charring wood is a step-by-step process an experienced person should do. Here’s a general overview of the process:

Wood Selection

The first step begins with choosing the wood. Choosing a suitable wood species for charring is not very difficult. Softwoods such as Japanese red cedar, Spruce, Hemlock, cypress or pine are commonly used because of their natural resistance and durability. However, hardwood can also be used, such as Oak.

Preparation

Prepare the wood surface by thoroughly cleaning it of any dirt, dust or debris. You can sand or scrub it with a brush. If the surface is not smooth, then the wood can be milled or planed to get a smooth surface.

Now we are ready to move on to the next step of charring.

Charring

The charring process usually involves using an open flame or blowtorch to scorch the surface of the wood. Here’s a step-by-step process:

- Light the flame or turn on the blowtorch.

- Hold the flame or blowtorch a few inches away from the wood surface.

- Move the flame along the wood, applying heat evenly to achieve uniform charring.

- Continue this process until the desired level of charring is achieved. Depending on personal preference, this can range from a mild to a heavy burn.

Cooling

After charring, the temperature of the wood can be very high. So allow the charred wood to cool down naturally.

Brushing and Cleaning

After cooling, use a wire brush, stiff-bristled brush, or nylon brush to remove soot and ash from the charred surface. This brushing process helps to reveal the texture of the wood.

Finishing (optional)

Finishing is optional but recommended. You can apply a wood sealer, oil or finish to the burnt wood. It enhances appearance and durability. It also protects the surface from moisture or insect attack.

Wood charring can be a difficult and dangerous job. The temperature of a blowtorch can be up to about 1100 degrees Celsius. So if you are planning to do wood charring for the first time, you must be careful. It is better to take the help of an experienced person who has done this before.

Burnt Wood Pros and Cons

Pros

- Insect and rot resistance: Shou sugi ban, a traditional Japanese technique of charring wood, makes it more resistant to insects and rot. This process makes it suitable for applications where durability and longevity are essential, such as outdoor furniture, fencing, or raised garden beds.

- Aesthetic Appeal: Burnt wood has a unique and distinctive appearance that adds a rustic, modern or artistic touch to architectural and wooden projects.

- Durability: The charring process changes the internal wood’s structure, making it more durable than ordinary wood. This increased durability can be advantageous for outdoor applications.

- Fire-resistant: Another advantage is that Shou Sugi Ban wood is more fire-resistant than ordinary wood.

- Low Maintenance: Burnt wood requires minimal maintenance compared to other types of wood. It does not require painting, staining or sealing, which can save time and effort.

Cons

- Cost: Shou Sugi Ban can be more expensive than untreated or traditional wood. Main reasons for being expensive: The charring process involves extra labor and specialized techniques.

- Limited Availability: Not all wood species are suitable for charring; this limited availability may limit the options for using charred wood in specific projects.

- Dust accumulation: The charring process results in small cracks or roughness on the surface of the wood. Which leads to the accumulation of dust on the wood.

FAQ

Does burning wood make it waterproof?

The short answer is yes. The Shou Sugi Ban process makes the wood highly moisture and weather resistant. When wood burns, it is wrapped in a thin layer of carbon and shrinks its cells, minimizing moisture absorption and increasing water resistance. But this does not mean that the charred wood becomes completely waterproof, which can withstand continuous exposure to water for a long time.

If you are looking for a specifically waterproof wood, there are alternatives available such as pressure-treated wood, some hardwood species such as Iroko, Oak, Western Red Cedar, Cherry, Maple, or wood that has been sealed to increase water resistance.

Do termites eat burnt wood?

Termites are generally not attracted to feed on burnt wood. The charring process changes the structure, burns the cellulose of the wood and makes it less attractive to termites as a food source.

Is burnt wood fireproof?

Yes, Burnt wood has better fire resistance. The charred layer acts as a protective barrier, slowing the spread of flames and reducing the risk of fire damage.

Where to Buy Shou Sugi Ban?

Shou Sugi Ban can be purchased from various sources, such as Specialty Lumber Suppliers, Local Woodworking or Carpentry Shops, Online Retailers, and Local Construction or Building Material Suppliers.

Always buy from a trusted supplier, dealer or online source to avoid getting scammed.